Building a wall using concrete masonry units (CMUs) can be a major investment of materials, labour and cost — and one of the first questions a builder, DIYer or estimator asks is: How many blocks do I need? This is where a good CMU Block Calculator comes in handy: a tool that turns wall dimensions, block size, joint thickness and other variables into a clear estimate of how many CMUs you’ll order, how much mortar to mix, and what waste to plan for.

On AllUtilityTools.com, we’ve built a feature (the “CMU Block Calculator”) to make this process fast, accurate and user-friendly. In this article you will learn:

- What a CMU block calculator is and why it matters

- How it works (the formulas behind it)

- What inputs you must gather (and why)

- Step-by-step how to use our calculator

- Tips and pitfalls for better accuracy

- Frequently asked questions (FAQ)

- Why using this calculator helps you with budgeting, ordering and construction efficiency

Let’s dive in.

- What is a CMU Block Calculator and Why You Should Use One

What is “CMU”?

“CMU” stands for Concrete Masonry Unit — the standard concrete block in the U.S. and many other markets. These blocks come in many sizes, but a typical size is 8″ × 8″ × 16″ (nominal). According to industry calculators, one standard 8 × 8 × 16 block covers about 0.889 ft² of wall face (including allowance for mortar joint).

Because the number of blocks and associated materials (mortar, reinforcement, grout) depend on wall size, block size and other factors, a CMU block calculator helps to estimate:

- The total number of blocks needed for a wall (or several walls)

- The amount of waste or extra blocks to order

- The amount of mortar, sand, and grout required (if applicable)

- The associated cost or budget estimate (if you provide unit costs)

Why it matters

When you mis-estimate your block quantity you can suffer:

- Under-ordering: Running out of blocks mid-job, causing delays

- Over-ordering: Wasting money, storage headaches, broken/damaged blocks

- Poor budgeting: If you don’t know the true cost, your project may balloon

- Material mismatch: Block size or joint issues cause unexpected cuts/waste

A good calculator saves time, avoids guesswork, and helps you order only what you need. For professional estimators and DIYers alike, getting this right improves efficiency and cost control.

- How the CMU Block Calculator Works Behind the Scenes

While our user interface does the math for you, it’s helpful to understand the formulas so you can trust the output and check for reasonableness. Below are the key concepts and formulas used in CMU block estimation.

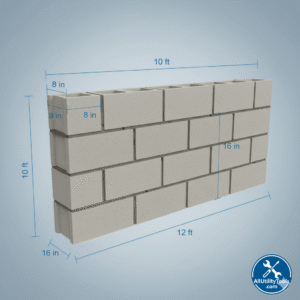

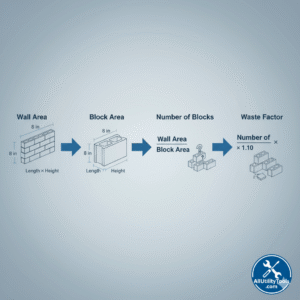

Wall area and block face area

- Wall Area = Wall Height × Wall Length (in your chosen units, e.g., ft or m)

- Block Face Area = (Block face width × Block face height) including mortar joint size

- For example: An 8 × 8 × 16 inch nominal block may have an actual face area ~0.889 ft² (including mortar).

- Number of Blocks ≈ Wall Area ÷ Block Face Area

Waste allowance

Since there are cuts, breakage, corners, special pieces, you should add a waste factor (commonly around 3–7%). For example, if you estimate 1000 blocks, adding 5% waste means ordering 1,050 blocks.

Mortar and other materials

Once you know number of blocks, you can estimate other materials:

- Mortar bags: Some calculators assume ~7 bags of masonry cement per 100 blocks (depending on block size).

- Grout / fill: For grouted or solid-filled walls (vertical cells, etc), the volume of grout required can be calculated as a function of wall area, block thickness, and fill percentage.

Example formula summary

From one estimator:

“Blocks per ft² ≈ 1 ÷ 0.888 ≈ 1.125” for an 8 × 8 × 16 module.

In other words: ~1.125 standard blocks per square foot of wall face (for that module size) when factoring the mortar joint.

- What Inputs You Need Before Using a CMU Calculator

To get an accurate estimate you need to collect the following information. The more precise your inputs, the more reliable the output.

- a) Wall dimensions

- Length (in feet/meters) for each wall run

- Height (in feet/meters)

- If the project has multiple wall sections with different sizes, measure each separately

- b) Block size (module)

- Nominal size of CMU: e.g., 8 × 8 × 16, 6 × 8 × 16, 12 × 8 × 16 (in inches)

- Actual face module including mortar joint (for example: 7 ⅝″ × 15 ⅝″ for nominal 8 × 8 × 16).

- You may need to enter custom size if blocks differ

- c) Mortar joint thickness

- Typical mortar joint in U.S. is 3/8″ (≈ 0.375″) for standard CMU blocks.

- If your job uses a different thickness, specify it

- d) Waste/over-order allowance

- Typical waste factor ranges: 3%–10%. For cuts, broken blocks, damaged units.

- Enter a percentage you’re comfortable with

- e) Openings (optional but helpful)

- If your wall has doors/windows/openings, you should subtract the area of those from the wall area, so you don’t over-order blocks. Some calculators allow you to enter openings.

- f) Grout / fill conditions (if applicable)

- If you plan to grout certain cores or fill all vertical cells, you’ll need: thickness of wall, spacing of vertical reinforcement, fill percentage (all cells vs spaced), etc.

By entering these inputs, the calculator can provide realistic block quantities, and often additional outputs such as mortar bag counts, grout volume, and cost estimates.

- How to Use the CMU Block Calculator on AllUtilityTools.com

Here is a step-by-step guide to using the CMU Block Calculator on your site. Following the steps will help ensure you get a meaningful estimate.

- Select Units: Choose whether you’re working in imperial (feet/inches) or metric (meters/mm).

- Enter Wall Length and Height: For each wall run, input the length and height. If you have multiple walls, some calculators allow you to add multiple sections.

- Choose Block Size: From the dropdown choose the nominal size of the block you are using (e.g., 8 × 8 × 16). If your block size is custom, enter actual dimensions.

- Enter Mortar Joint Thickness: Default may be 3/8″; change if your project uses different mortar thickness.

- Openings: If you have doors or windows, enter width and height of each opening. The calculator will subtract their area from the wall area.

- Waste Percentage: Enter a waste allowance percentage (e.g., 5 %).

- Grout / fill options (optional): If you wish to estimate grout fill, specify wall thickness, fill conditions (every cell, vertical spacing etc.).

- Click “Calculate”: The tool will compute:

- Total wall area (gross and net after openings)

- Face area per block (based on module)

- Number of blocks required

- Blocks to order (including waste)

- Mortar bags estimate (if included)

- Grout volume (if included)

- Review results: Round up when ordering. Keep a buffer for cuts or unforeseen needs.

- Optional – Cost estimate: Multiply blocks by the unit cost (entered manually) to get material cost.

Tip: After you get the number, walk the job site and verify your wall lengths and heights visually. Small errors in measurement multiply quickly.

- Tips and Pitfalls: How to Improve Accuracy & Avoid Mistakes

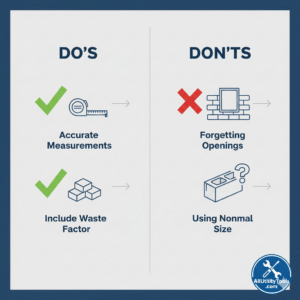

✔️ Use actual face module (including joint)

Many people use nominal block size (8 × 8 × 16) but forget that the actual laid size is slightly smaller (because of mortar joint). This can cause under- or over-estimate. For example, one calculator shows face area for 8×8×16 module ≈ 0.888 ft².

✔️ Account for openings and special conditions

If there are many windows, doors, or unusual wall shapes, subtract their area so you don’t pay for blocks you won’t use.

✔️ Consider reinforcement and bond beams

If your wall has bond beams (horizontal reinforced courses) or fully-grouted cells, you’ll need to adjust material estimates. Some calculators don’t include these by default.

✔️ Don’t forget waste / breakage allowance

Blocks can crack during transport, cutting, or handling. A 5% waste allowance is common. For very complex walls, you might use 7–10%.

✔️ Round up when ordering

Always round up to whole units. For example, if the calculator says 1023 blocks, ordering 1023 is risky. Round to 1050 or whatever nearest pallet quantity your supplier uses.

✔️ Review supplier block unit cost

If you are also estimating cost, make sure your block unit cost matches the size and configuration (hollow vs solid, architectural finish vs standard).

✔️ Double-check all dimensions

Minor mistakes like entering 25 ft instead of 25.0 ft, or mixing feet and meters can skew results. Use consistent units.

✔️ Consider stock or lead time

Block supply may have lead times, especially for unusual sizes or finishes. Order early once you estimate.

✔️ Use the results for all materials

While the calculator may focus on blocks, use the output to plan mortar, sand, grout, and reinforcing so you purchase all materials in sync.

- Frequently Asked Questions (FAQ)

Q1: Can I use the CMU block calculator for small walls or garden walls?

Yes — the same principles apply. Although for low-height walls you may ignore reinforcement or special structural features, you still benefit from accurate block counts and waste allowances.

Q2: What block size should I enter if my blocks are 8″ thick but 16″ tall/long?

Enter the nominal face module that matches your units. For example, 8 × 8 × 16 (nominal) is common; check actual face dimensions with your supplier and ensure joint thickness is included.

Q3: Does the calculator account for bond beams or vertical rebar fill?

Not always by default. Some calculators provide a separate section for grout/ fill volume (vertical cells) or bond-beam calculation. If your wall includes those, use the additional options or calculate those separately.

Q4: What mortar joint thickness should I use?

In many U.S. projects, the standard mortar joint is 3/8″ (≈ 0.375″). However if your project uses a different thickness (e.g., ¼″ or ½″), enter that value into the calculator.

Q5: How accurate are these calculators?

They provide good estimates and are extremely useful for planning and ordering. However, actual on-site usage may differ due to workmanship, cutting waste, block variation, and project complexity. Always include a safety buffer and cross-check once materials are delivered.

Q6: Can I use the calculator internationally (metric units)?

Yes. Many calculators support both imperial (feet/inches) and metric (meters/mm) units. Select the correct unit system before entering your data.

- Why the CMU Block Calculator Helps with Budgeting, Ordering and Construction Efficiency

Budgeting

When you know the number of blocks, you can multiply by unit cost and get a realistic material budget. Add mortar, sand, grout and labour to build a complete cost picture. This supports project bids, client funding and cost control.

Ordering

Accurate block counts reduce order errors: you avoid paying for extra unused blocks or facing delays because you under-ordered. With waste allowance built in, you’re better prepared.

Construction efficiency

On-site, knowing the block count lets your team schedule block deliveries, coordinate mortar and sand batches, plan cutting and layout, anticipate special blocks (corners, half-blocks). This improves workflow.

Improved supplier coordination

Providing your block supplier with accurate quantities (and sizes) helps them schedule shipments, package pallets correctly, and avoid unexpected surcharges for small orders or unusual sizes.

Risk mitigation

By building an estimate early, you can identify high waste areas (complex shapes, many openings) and plan alternative layouts or block sizes to reduce cost. You also avoid the common problem of “oh crap, we estimated 800 and we used 950”.

- Real-World Example Walk-Through

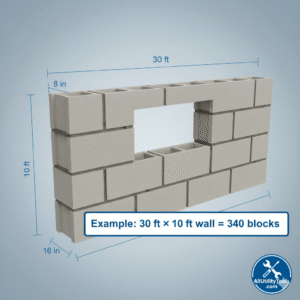

Let’s walk through a sample scenario (with rounded numbers) to show how our calculator works in practice.

Scenario: You are building a straight wall, 30 ft long and 10 ft high, using standard nominal 8 × 8 × 16 CMU blocks, with a mortar joint of 3/8″. There is one window opening of 4 ft wide × 3 ft high. You plan 5% waste.

- Wall gross area = 30 ft × 10 ft = 300 ft²

- Opening area = 4 ft × 3 ft = 12 ft²

- Net wall area = 300 ft² − 12 ft² = 288 ft²

- Block face area (approx) = 0.889 ft² (for 8×8×16 block including joint).

- Blocks needed (net) ≈ 288 ÷ 0.889 ≈ 324 blocks

- Waste allowance (5%) → 324 × 1.05 ≈ 340 blocks (round up to order)

- Entering this into the calculator will display the number of blocks, number of mortar bags (based on formula), etc.

From this you can present the block quantity to your supplier, multiply by unit cost (say $2.50 per block) → $850 material cost (340 × $2.50). You may also estimate mortar: if your calculator says ~7 bags per 100 blocks, for 340 blocks you need ~24 bags of mortar cement.

This simple example shows how quick and useful the calculator is.

- Final Thoughts

Estimating CMU block quantity accurately is a major step in any masonry project. With the right inputs, a dependable calculator and awareness of real-world factors (opening deductions, waste allowance, actual block size) you can significantly reduce cost, avoid delays and increase efficiency.

At AllUtilityTools.com, our CMU Block Calculator is designed to simplify this process while giving you flexibility: whether you’re a contractor ordering pallets for a large job or a homeowner planning a DIY wall, this tool works for you.

Remember: the output is only as good as the input. Measure carefully, choose the correct block size, account for openings and waste, and you’ll have a reliable estimate you can act on.

If you have any special conditions (curved walls, reinforced stem walls, architectural CMU, split-face finish) or need assistance interpreting the results, feel free to contact us or check our blog for advanced estimation articles.

Thank you for reading. Now go ahead, try our CMU Block Calculator, and get your estimation right from the start.